Amazing Info About How To Build A Contact Mic

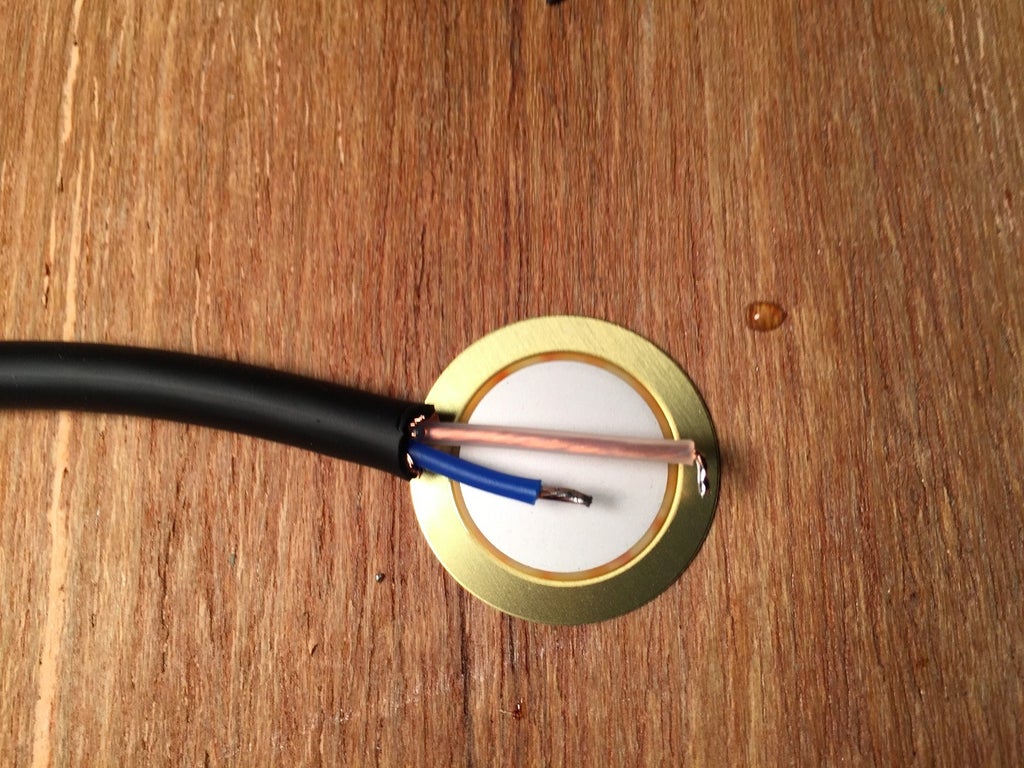

Mic lead glued in position.

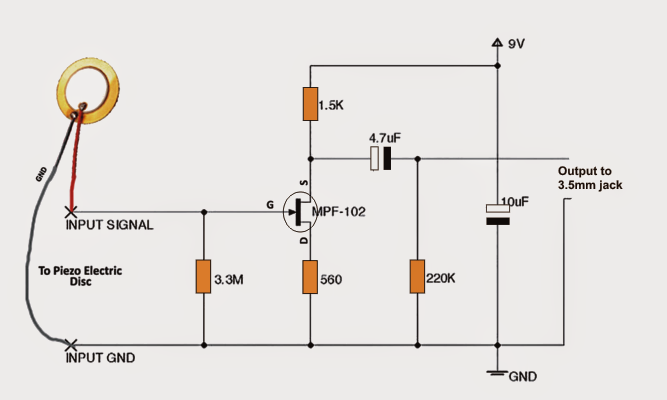

How to build a contact mic. We teamed up with our friends at micparts.com to build a custom mic and upgrade an existing mic. You can further secure both the mic and cable using gaffer tape, which holds firm but peels off without leaving. This will prevent the piezo disc from damage and keep the wires from.

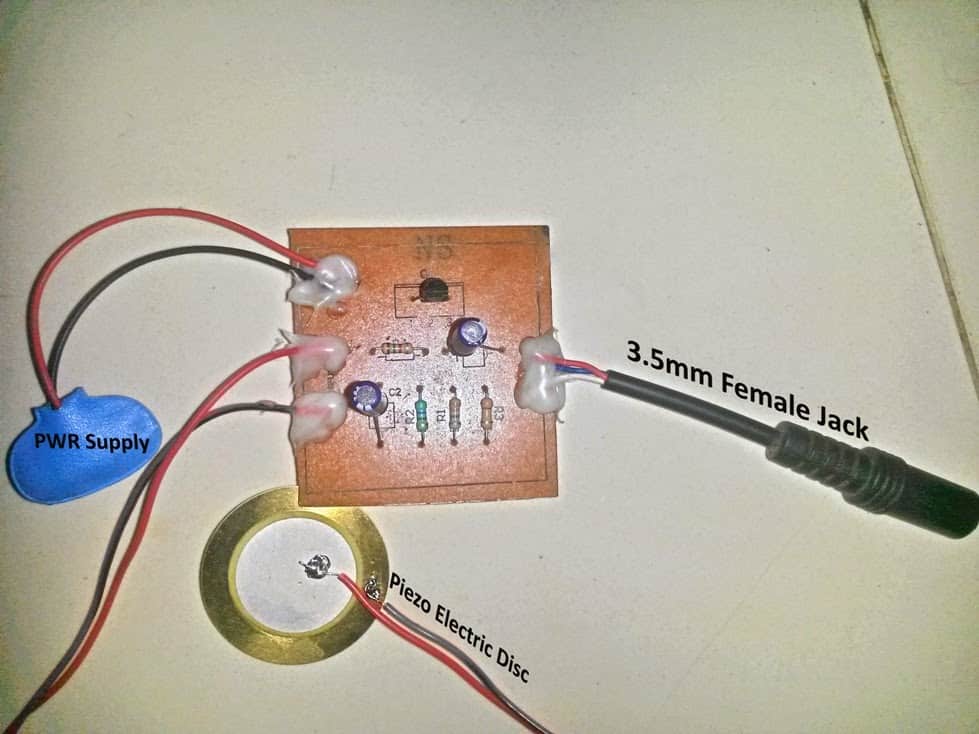

Hold the tape in place and creased with two more pieces of tape on each end. I coated the mic cable with hot glue and pulled it through the chimney, then splurged lots more glue where the wires enter the can. Next i reinforced the solder joints with hot glue and.

Build your microphone locker diy style! The diy microphone is inspired by a video from diy perks. So the first thing i did was to hot glue cardboard inside the lid to make the piezo disc able to lay flat against any surface i attach it to.

All of my search term words; In order to make your contact mic more robust, apply a large dab of epoxy to the top of the element. He gives a detailed explanation on how to build this microphone in this video:

Ok let’s get to work. Any of my search term words; Looking to go electric on the cheap?

Place the soldered piezo disc on the tape and secure the cable to the table with another piece of masking tape. Attach the contact mic to the guitar top using a bit of poster mounting putty.